HBI Fines

HBI fines are iron-based particulates with Fe content as high as > 85% produced during the production process and handling of DRI (A) briquettes (HBI) and DRI (B) pellets/lumps(sponge iron).

Economic value:

HBI fines is an iron rich material with low impurity levels making it a good alternative for iron ore and scrap in steel making industry and a better choice for steel manufacturers to increase productivity and improve quality while reducing the costs.

Industrial Applications:

The main application of HBI fines is in the field of iron and steelmaking industry as it’s used in sinter mix which agglomerates the fines to be used in blast furnace and also the fines can be compacted to be used as feedstock for electric arc furnace as DRI.

Generation of HBI fines:

Fines are generated due to:

1. During the production, transportation and storage of DRI and HBI, large quantities of small particles or dust are produced; these are known as fines.

2. As EAF process requires minimal content of fines in the charge, DRI and HBI are screened before shipment thus fines will also be generated.

3. Also during the production process the off-gas system produces off-gas fines which are a mixture of reduced and un-reduced fines thus have a lower range of metallic iron than DRI fines.

This dust or fines is of relatively high value as it has a high metal content. At the end all types of fines are collected and stored in the open until sufficient quantity is accumulated. Then screened to remove oversized particles and blended to meet customer requirements.

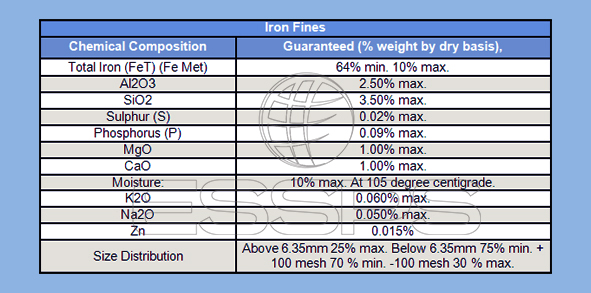

Characteristics of HBI fines:

Physical characteristics:

Black colored fines, generated during the manufacture and handling of DRI and HBI. The particle size depends on the feedstock and can range from 0 to 12 mm. The density of HBI Fines is less than 5,000 Kg/m³ with moisture content ranges from 0.3 percent up to 12 percent.

Chemical characteristics:

HBI fines contains 90-94% total Fe, of which 80-90% is metallic Fe and low residual metallic materials. There are two forms of iron in DRI. One is metallic form which is known as metallic iron, Fe (M), and the second form of iron which is present in residual iron oxides, Fe (O).

Fines are stable under normal conditions, Unstable when wet, oxidizes with fresh water and more readily with sea water forming rust and generation of Hydrogen Gas.

Our product:

We are ready to supply HBI fines worldwide, in any quantity, specification and packing as per customers’ requirements.