DRI Fines

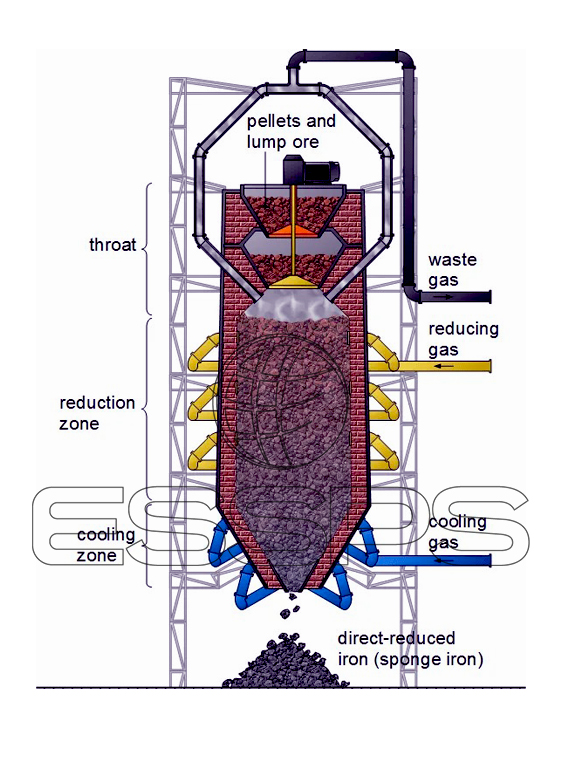

Direct Reduced Iron (DRI) also known as Sponge iron is produced by the direct reduction of iron ore in the solid state without subjecting the ore or the metal to fusion, the reduction occurs by carbon monoxide (CO) and hydrogen (H2) derived from natural gas or coal, it has high Fe concentration and low residual metallic materials, it can be produced in pellets/lumps or fines.

Economic value and industrial applications:

DRI is an iron rich material with low impurity levels making it a good alternative for scrap in steel making industry and a better choice for steel manufacturers to increase productivity and improve quality as DRI is considered to be a source of clean iron that can be used to produce high quality iron and steel products.

The main application of DRI is as an alternative for scrap in the electric arc furnace as it is easier to handle than scrap and can be continuously fed to the furnace, also there are other benefits that make DRI takes advantage over Scrap such as; low residual elements content, melt consistency, uniform and predictable mass and chemical analysis and its carbon content that can be adjusted to the EAF process requirements.

DRI production process:

DRI is produced by mixing iron ore with a reductant (gas or solid) which is also used for heating the ore bed to the temperature needed to achieve adequate reduction rates but below the iron melting point. DRI production processes are either natural gas based or coal based.

Types of DRI:

DRI is produced either as DRI (B) pellet/lump form or as DRI(A) which is Hot Briquetted iron HBI, the principal application for both types is as alternative for scrap and metallic feedstock for electric arc furnace (EAF).

Characteristics of DRI:

Physical characteristics:

Solid light grey material in a form of pellets/lumps, it has no odor and in-soluble in water.

DRI has low apparent density, great porosity and large surface area as compared to iron ore, this occurs due to the removal of oxygen in the reduction process which make it more porous and have voids like sponge when it’s viewed under the microscope.

Chemical Characteristics:

DRI contains 90-94% total Fe, of which 80-90% is metallic Fe and low residual metallic materials. There are two forms of iron in DRI. One is metallic form which is known as metallic iron, Fe (M), and the second form of iron which is present in residual iron oxides, Fe (O).

DRI is stable under normal conditions, Unstable when wet, oxidizes with fresh water and more readily with sea water forming rust and generation of Hydrogen Gas.

Our product:

We at Dahab logistics are ready to supply DRI worldwide, with full customer support to ensure that all the customers’ requirements are met including quality, quantity, packaging and shipment to fulfil customers’ satisfaction.

For Specifications and Quotation Contact us.

الحديد المختزل او ما يعرف بالحديد الاسفنجي هو حديد عالي الجودة ينتج عن طريق اختزال خام الحديد في حالته الصلبة بواسطة اول أكسيد الكربون و الهيدروجين المشتقان من الغاز الطبيعي او الفحم و تتم عملية الاختزال في افران الاختزال المباشر في درجة حرارة عالية و لكن اقل من درجة انصهار الحديد وسمي الحديد الاسفنجي بهذا الاسم نظرا لتركيبه الداخلي الذي يشبه الاسفنج و ذلك نتيجة لانتزاع جزيئات الاكسجين اثناء عملية الاختزال.

ويستخدم الحديد المختزل كبديل للخردة في افران القوس الكهربي حيث انه يحتوي علي نسبة عالية من الحديد قد تصل الي 98% مع نسبة قليلة جدا من الشوائب و العناصر الأخرى مما يجعله البديل الأفضل للخردة لانتاج صلب عالي الجودة و أيضا لتقليل تكلفة شراء الخردة حيث ان عملية انتاج الحديد المختزل موفرة نظرا لاعتمادها على الغاز الطبيعي